A quiet agricultural revolution is on the horizon in parts of China. Innovative anaerobic digestion techniques are revolutionizing agriculture by transforming livestock manure into organic fertilizer and clean biogas energy. As these technologies significantly lower carbon emissions, they can set a precedent for sustainable farming practices across China and the world.

Food and agriculture generate nearly 31% of global greenhouse gas (GHG) emissions. Of that total, the six top emitting economies – China, Indonesia, the United States, Brazil, the EU, and India – contribute 51% of these food system’s emissions.

As researchers at the Beijing-based Institute for Global Decarbonization Progress, we were interested in better understanding China’s footprint in this area. So we mapped out China’s decarbonization pathways in its agrifood system. In 2014, China’s agricultural GHG emissions hit 1,198 metric tons of CO2e. We discovered that livestock manure management contributes over 19% of the nitrous oxide and 14% of the methane in these emissions.

This is important because methane and nitrous oxide are super climate pollutants on the rise from booming livestock operations. Better manure management could be an area in which China might make progress in deep decarbonization, especially since manure can be converted into energy and fertilizer resources for farmers.

So how is China doing? In May 2023, our team visited an agricultural waste utilization operation in Nanchang, Jiangxi Province, to see firsthand how local actors are putting manure to use.

Transforming Animal Waste to a Resource

As China’s living standards have risen over the past 30 years, the demand for meat has skyrocketed. One consequence is that livestock manure has increased 25%, reaching 2.6 billion tons in 2018. (This total equals the weight of all the food that humans consume worldwide each year). And besides increasing GHG emissions, the lack of good manure management also has created harmful water pollution in China.

A climate-smart solution of “cooking” the manure in an anaerobic digester can turn livestock manure into two useful products: organic fertilizer and biogas. The use of a digester sanitizes the solids into organic fertilizer—and then captures the methane to make biogas energy.

Using organic fertilizer from manure improves soil quality and crop yields. Its production also uses less energy and generates less GHG emissions than chemical fertilizer manufacturing. Turning manure into biogas offers a double benefit: controlling methane and providing clean energy to farms and local communities.

Despite these benefits, however, most Chinese farms lack anaerobic digesters because the up-front construction costs to create them are too high. Another obstacle? Over 70% of China’s farms specialize in producing either livestock or crops. This means that livestock farmers who install anaerobic digesters also must foot the bill to transport the organic fertilizer to crop farms.

Regulators often face difficulties in monitoring the sewage of China’s many small and widely dispersed livestock farms. Some individual farmers discharge livestock manure directly into ponds. Their decision to contaminate underground water is taken because they do not feel any regulatory pressure to treat this waste.

To overcome these obstacles for climate-smart manure management, Chinese policymakers must create incentives for dedicated third-party enterprises to collect and treat agricultural waste as a resource—and to invest in anaerobic digester facilities.

Policymakers and Poop

Policymakers have caught a whiff of the challenges posed by manure. So they have issued policies and regulations to convert China’s sizable agricultural waste into resources. China’s 2022 Nationally Determined Contributions – the national climate actions at the heart of the Paris Agreement – include a number of agricultural GHG mitigation measures such as fertilizer use reduction, ecosystem carbon sinks, and waste resource utilization. The ministries of agriculture, environment, and science and technology all promote the utilization of livestock manure in significant ways.

China hit the targets on its 2017 Policy Guidance on Accelerating the Resource Utilization of Animal Manure. These guidelines called for a livestock manure utilization rate of over 75% by 2020, as well as for at least 95% of large-scale livestock farms to have manure treatment infrastructure.

Subsequent efforts have increased this output. The manure utilization rate was increased to 80% in 2025 and 90% in 2035 under the 2019’s Guiding Opinions on Promoting the Land Application of Livestock Manure and Strengthening the Pollution Control.

A Journey South to See a New Ecological Recycling Model

Jiangxi Province is an important livestock production base where farmers have practiced a “pig-methane-fruit” approach for resource utilization since the 1990s. This particular model links livestock farming and planting in rural areas via biogas and slurry. Manure from livestock is combined with village waste and placed into a biogas digester. After anaerobic fermentation, the biogas is used for cooking, water heating, and lighting. The remaining slurry is used as fertilizer for fruits and vegetables.

But the “pig-methane-fruit” model cannot keep pace with the increasing size and intensity of livestock farming in the region. The manure and sewage generated by animals and people exceed the capacity that farmland can absorb. So Jiangxi, like other provinces, struggles with the untreated manure that remains polluting local waterways.

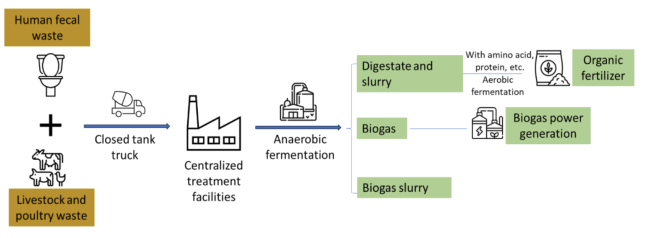

The Zhenghe Environmental Protection Group (ZEPG) has created an N2N ecological recycling agriculture model (see figure below) as a new solution. This system connects N upstream breeding farms with N downstream crop farms, placing biogas generation and organic fertilizer centers in between them. The local government provided ZEPG with non-farm land to build treatment plants. These officials also set up public-private partnerships for investment, and passed policies to facilitate manure collection. The N2N model has been promulgated in three Jiangxi counties to reduce pollution, capture agricultural waste, and produce biogas energy and organic fertilizer at scale.

In addition, ZEPG has built the Ecological Agricultural Science and Technology Park in the town of Liuhu in Nanchang, which gathers farmland waste from 229 large-scale farms. Rural and public toilets are also tied into the park in order to facilitate the co-treatment of human and livestock fecal waste. After being collected, this waste is delivered to a central processing center for anaerobic fermentation. Part of the generated biogas from this process also powers the technology park itself.

The Ecological Agricultural Science and Technology Park processes 300,000 tons of manure and produces 5 million cubic meters of biogas annually. This biogas generates enough electricity to produce surplus organic fertilizers for sale, thus reducing 18,000 tons CO2 by replacing chemical fertilizers. Farmers pay the Liuhu Park 10 RMB ($1.37) per ton of manure treated. This price is not a huge financial burden to the farmers, but it greatly helps generate funds for the plant’s operating costs.

The N2N model meets the government’s requirement that crop farms be able obtain organic fertilizers from a nearby source. Monitoring pollution leakage from farms through a third-party site that centralizes agricultural waste treatment is also easier.

Taken together, these factors are potent ways to lower agricultural pollution and carbon emissions. These Jiangxi pilots provide a roadmap for a low-carbon agriculture solution to manure waste across China.

In addition, ZEPG has built the Ecological Agricultural Science and Technology Park in the town of Liuhu in Nanchang, which gathers farmland waste from 229 large-scale farms. Rural and public toilets are also tied into the park in order to facilitate the co-treatment of human and livestock fecal waste. After being collected, this waste is delivered to a central processing center for anaerobic fermentation. Part of the generated biogas from this process also powers the technology park itself.

The Ecological Agricultural Science and Technology Park processes 300,000 tons of manure and produces 5 million cubic meters of biogas annually. This biogas generates enough electricity to produce surplus organic fertilizers for sale, thus reducing 18,000 tons CO2 by replacing chemical fertilizers. Farmers pay the Liuhu Park 10 RMB ($1.37) per ton of manure treated. This price is not a huge financial burden to the farmers, but it greatly helps generate funds for the plant’s operating costs.

The N2N model meets the government’s requirement that crop farms be able obtain organic fertilizers from a nearby source. Monitoring pollution leakage from farms through a third-party site that centralizes agricultural waste treatment is also easier.

Taken together, these factors are potent ways to lower agricultural pollution and carbon emissions. These Jiangxi pilots provide a roadmap for a low-carbon agriculture solution to manure waste across China.

This article is part of a Wilson Center-Ohio State University Cultivating US and Chinese Climate Leadership on Food and Agriculture project.

Zhu Tongxin is an Assistant Analyst at the Institute for Global Decarbonization Progress (iGDP), a climate policy nonprofit consultancy based in Beijing. Her research focuses on non-CO2 emissions reduction and China’s sustainable agri-food transition.

Diego Montero is Strategy Director at iGDP.

Top Photo Credit: Workers are adjusting the manual mixing valve outside the anaerobic fermentation tank in a biogas power station, North China. Photo courtesy of chinahbzyg/shutterstock.com

Infographic Credit: iGDP

Sources: China Science Communication, China’s Ministry of Agriculture and Rural Affairs, China’s National People’s Congress, CNfood, Future of Food, IGDP, JXNews, Science Direct, Wilson Center

In addition, ZEPG has built the Ecological Agricultural Science and Technology Park in the town of Liuhu in Nanchang, which gathers farmland waste from 229 large-scale farms. Rural and public toilets are also tied into the park in order to facilitate the co-treatment of human and livestock fecal waste. After being collected, this waste is delivered to a central processing center for anaerobic fermentation. Part of the generated biogas from this process also powers the technology park itself.

The Ecological Agricultural Science and Technology Park processes 300,000 tons of manure and produces 5 million cubic meters of biogas annually. This biogas generates enough electricity to produce surplus organic fertilizers for sale, thus reducing 18,000 tons CO2 by replacing chemical fertilizers. Farmers pay the Liuhu Park 10 RMB ($1.37) per ton of manure treated. This price is not a huge financial burden to the farmers, but it greatly helps generate funds for the plant’s operating costs.

The N2N model meets the government’s requirement that crop farms be able obtain organic fertilizers from a nearby source. Monitoring pollution leakage from farms through a third-party site that centralizes agricultural waste treatment is also easier.

Taken together, these factors are potent ways to lower agricultural pollution and carbon emissions. These Jiangxi pilots provide a roadmap for a low-carbon agriculture solution to manure waste across China.

This article is part of a Wilson Center-Ohio State University Cultivating US and Chinese Climate Leadership on Food and Agriculture project. Zhu Tongxin is an Assistant Analyst at the Institute for Global Decarbonization Progress (iGDP), a climate policy nonprofit consultancy based in Beijing. Her research focuses on non-CO2 emissions reduction and China’s sustainable agri-food transition. Diego Montero is Strategy Director at iGDP. Top Photo Credit: Workers are adjusting the manual mixing valve outside the anaerobic fermentation tank in a biogas power station, North China. Photo courtesy of chinahbzyg/shutterstock.com Infographic Credit: iGDP Sources: China Science Communication, China’s Ministry of Agriculture and Rural Affairs, China’s National People’s Congress, CNfood, Future of Food, IGDP, JXNews, Science Direct, Wilson Center

In addition, ZEPG has built the Ecological Agricultural Science and Technology Park in the town of Liuhu in Nanchang, which gathers farmland waste from 229 large-scale farms. Rural and public toilets are also tied into the park in order to facilitate the co-treatment of human and livestock fecal waste. After being collected, this waste is delivered to a central processing center for anaerobic fermentation. Part of the generated biogas from this process also powers the technology park itself.

The Ecological Agricultural Science and Technology Park processes 300,000 tons of manure and produces 5 million cubic meters of biogas annually. This biogas generates enough electricity to produce surplus organic fertilizers for sale, thus reducing 18,000 tons CO2 by replacing chemical fertilizers. Farmers pay the Liuhu Park 10 RMB ($1.37) per ton of manure treated. This price is not a huge financial burden to the farmers, but it greatly helps generate funds for the plant’s operating costs.

The N2N model meets the government’s requirement that crop farms be able obtain organic fertilizers from a nearby source. Monitoring pollution leakage from farms through a third-party site that centralizes agricultural waste treatment is also easier.

Taken together, these factors are potent ways to lower agricultural pollution and carbon emissions. These Jiangxi pilots provide a roadmap for a low-carbon agriculture solution to manure waste across China.

This article is part of a Wilson Center-Ohio State University Cultivating US and Chinese Climate Leadership on Food and Agriculture project. Zhu Tongxin is an Assistant Analyst at the Institute for Global Decarbonization Progress (iGDP), a climate policy nonprofit consultancy based in Beijing. Her research focuses on non-CO2 emissions reduction and China’s sustainable agri-food transition. Diego Montero is Strategy Director at iGDP. Top Photo Credit: Workers are adjusting the manual mixing valve outside the anaerobic fermentation tank in a biogas power station, North China. Photo courtesy of chinahbzyg/shutterstock.com Infographic Credit: iGDP Sources: China Science Communication, China’s Ministry of Agriculture and Rural Affairs, China’s National People’s Congress, CNfood, Future of Food, IGDP, JXNews, Science Direct, Wilson Center A Publication of the Stimson Center.

A Publication of the Stimson Center.